Quality Policy & Objectives

Precision. Performance. Perfection.

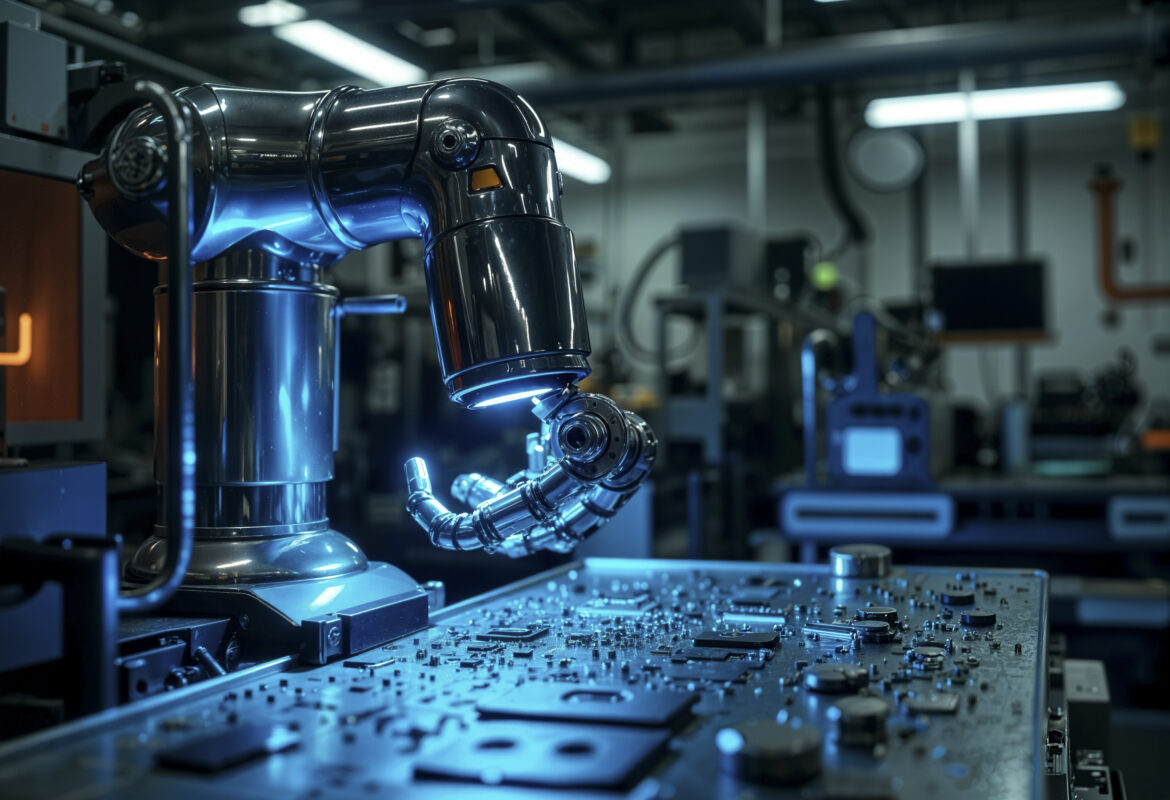

At TAVAS ELECTRON INTERCONNECTION PVT LTD quality is not just a requirement — it’s a culture embedded in every step of our process. We are committed to delivering zero-defect, high-reliability interconnect solutions that exceed customer expectations across Aerospace, Defense, Marine, and Space platforms.

Our approach to quality is proactive, process-driven, and standards-compliant — backed by a team that takes personal ownership of product excellence.

2D/3D Harness Design & Routing

Connector Selection & Optimization

Custom Mechanical Components

Design for Manufacturability (DFM)

Design for Testability (DFT)

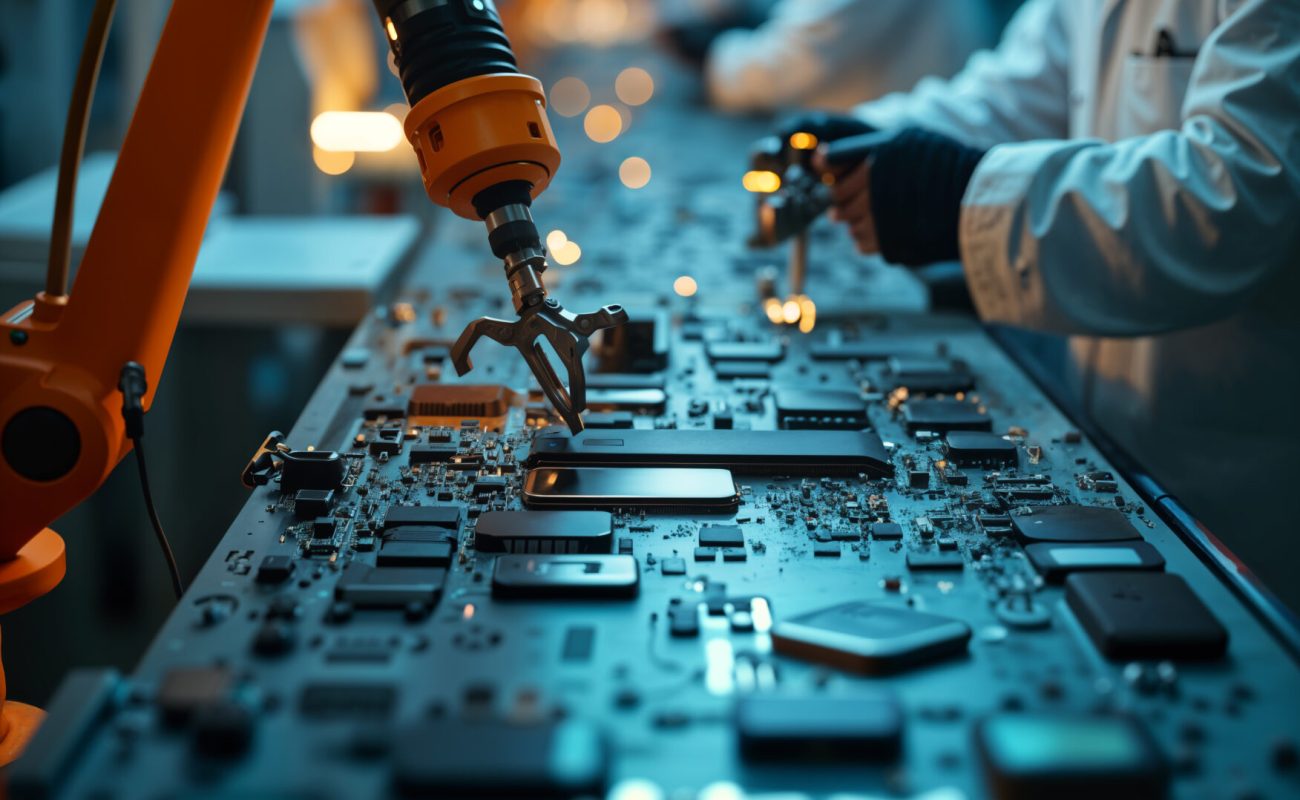

Our QMS is designed to:

Ensure process control and traceability from design through delivery

Identify and eliminate defects through root cause analysis and CAPA

Adapt to changing customer needs and evolving regulatory demands

Support our strategic goals of lean manufacturing and operational excellence

AS9100 Rev D / ISO 9001:2015 Certified Facility

First Article Inspection as per AS9102

IPC/WHMA-A-620, IPC-A-610, J-STD-001 Compliance

MIL-STD & JSS Environmental and Functional Testing

In-House Calibration & Inspection aligned with ISO 10012 & ASQC Z1.4/Z1.9

| T | Timely | On-time and safe delivery for every customer requirement |

| A | Accountability | Every employee owns quality as a personal responsibility |

| V | Value-Driven | Quality products and services that exceed expectations |

| A | Adaptability | Agile processes to meet changing needs and specifications |

| S | Satisfaction | Total customer satisfaction through consistent quality and performance |